PCB where is it found

July 4, 2022

PCB where is it found,PCB’s have changed and simplified the use of many electric appliances. From a desktop computer to high-end medical equipment, PCB’s are now simply everywhere.

Here’s a quick answer, then if you need one you can simply give us a call here at RayPCB. Otherwise, we’ll dive into some further information below.

What Products PCB’s Are Found In

PCB’s are found in almost every electronic device in some form or another. Below are some common types of devices in which you will find PCBs.

Consumer Electronics – This includes all the electronic items we use in our day to lives. From Audio and Video Systems, TV, Video and DVD players, Digital Cameras, Computers and Laptops, Mobile phones and GPS to Home and Kitchen appliances. This equipment very often uses standard PCB’s that are fairly standard and similar to each other.

Medical Devices– High-density PCB’s are found in medical devices. They support the test of new and advanced medical technologies with denser designs. This also reduces the complications in creating small-sized and light weight medical pcb equipment. PCB’s are found in all sized medical equipment, from small pacemakers to large X-ray and CAT machines.

Industrial Machinery– PCB’s are commonly found in high-powered industrial machinery. Thick copper PCB’S are usually found in industrial machinery to better fit heavy requirements. For example, industrial machines such as motor controllers, industrial load testers and high-current battery charges are where thick copper PCB’s can be found.

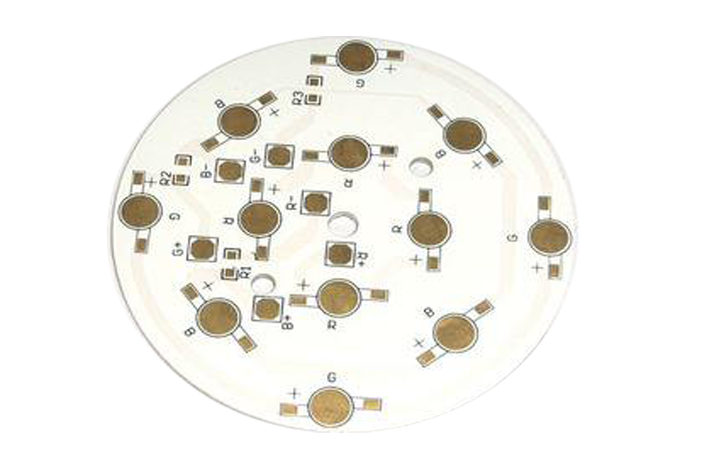

LED Applications– LED lights are another common equipment where PCBs are found, a more modern form of technology but still largely based on PCBs, and which is famous for more efficient electricity consumption. LED lights have PCB’S that perform as heat sinks allowing a high level of heat transfer than normal PCB’s. Even some other basic lighting solutions use these aluminum-backed PCB’s for high-level heat transfers.

Automotive and Aerospacerelated devices – PCB’s designed to withstand high vibrating environments are found in automotive and aerospace industry related devices. The vibrating nature in these industries is supported by flexible PCB’s. They can be very flexible in a way that can fit into very tight spaces designed within appliances. The PCB’s in these appliances can also be very lightweight and durable, which is essential when manufacturing parts for transporting, and in high impact, low weight requirement industries.

I hope this has helped you to understand more about where to find PCBs. Essentially they’re found everywhere and all around us in our daily lives. So let’s find out what it actually does.

What Kind of Function PCB’s Carry Out

The main function of a PCB is to house, and facilitate the smooth flow of electricity between required connected components, these components are built into the PCB. However, for a better understanding, below are few other different operations PCB’s do.

Resisting– Controlling the electricity flow is important in most electric appliances to avoid burnout. For this purpose, PCB’s have resistors that resist the value of electricity flowing according to their value.

Allocating – As mentioned above, PCB’s can be assembled easily. For this purpose, PCB’s have pads that are empty. These pads allocate space to easily solder any other electrical components when there is a need to.

Assembling– Yet again for easy assembling, PCB’s have letterings called “silk screening”. These help to identify what exactly a part is and the location for it through the letters.

Storing– For storing power PCB’s can house capacitors. These help to hold the charge and release them whenever electricity is needed for functioning.

Signalling through lights – PCB’s have small bulbs like diodes, that light up as a sign to show electricity running through.

Switchesfor controlling – PCB’s house switches to control the excessive flow of electricity between different components. These also help in regulating the heat from affecting the layers of the board.

Adding to these well-designed operations, PCB’s are also manufactured to better fit and suit any equipment. Let’s find out how!

The different types of PCBs available are

- Single-Sided PCBs

- Double-Sided PCBs

- Multilayer PCBs

- Rigid PCBs

- Flex PCBs

- Rigid-Flex PCBs

- Single-Sided PCBsSingle-Sided PCBs

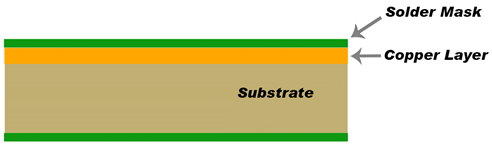

Single-Sided PCBs

A single-sided PCB is the most common type of printed circuit board. It has a single conductive copper layer above the substrate. The electrical components are soldered or placed on one side of the board, and the entire etched circuit is visible on the other. Since these boards only have one conducting layer, the conductive paths cannot intersect or overlap and hence take up a lot of space.

As a result, these PCBs are suitable for low-density design requirements. Single-sided printed circuit boards (PCBs) are used for basic and low-cost electrical/electronic instruments such as calculators, power supplies, LED lighting boards, FM radios, timing circuits, and so on.

Advantages of Single-Sided PCBs

Cost-effective

Easy to manufacture

Suitable for low-density designs

Easy to repair if in case something goes wrong

Easy to design

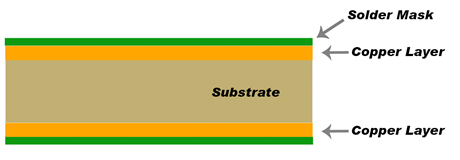

Double-Sided PCBs

A thin layer of conducting material, such as copper, is added to both the top and bottom sides of the board in a double-sided PCB. Holes in the circuit board allow metal parts to be connected from one side to the other. These PCBs connect the circuits on either side using one of two mounting methods, through-hole technology or surface mount technology. Through-hole technology entails installing lead components into pre-drilled holes on the circuit board, which are then soldered to pads on opposite sides. Surface mount technology entails the precise placement of electrical components on the surface of circuit boards.

Double-sided PCBs are used in a variety of applications such as cell phone systems, power monitoring, test equipment, amplifiers, HVAC application, UPS system, and many more.

Advantages of Double-Sided PCBs

Reduced size which makes circuit compact

Relatively lower cost

More flexible

Increased circuit density

Suitable for advanced electronic systems

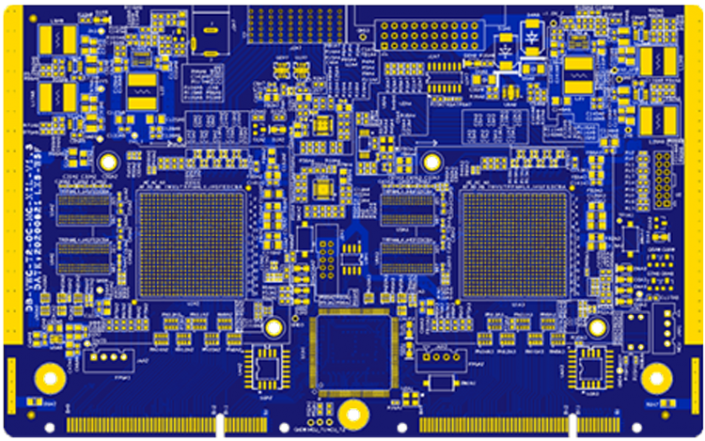

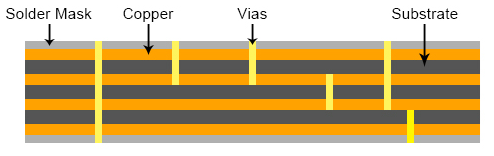

Multilayer PCBs have more than two copper layers. In general, any board featuring at least three conductive layers is included in this category. Multilayer PCBs are designed in a ‘sandwich’ fashion, with several double-sided conductive layers divided by an equal number of insulating material sheets. All of these must be bonded and laminated together under high pressures and temperatures to ensure that no air gaps exist and that the final PCB assembly is properly stable.

Multi-layer PCBs are used in computers, laptops, mobile phones, tablets, medical equipment, GPS trackers, and many other more complex circuits and devices.

Advantages of Multi-Layer PCBs

Compact in size

More robust

High level of design flexibility

Suitable for high-speed circuits

Rigid PCBs

As the name implies, a rigid PCB is a circuit board that cannot be twisted or folded. The board’s base material is a rigid substrate, which gives the board rigidity and strength. They are composed of multiple layers including a substrate layer, a copper layer, a solder mask layer, and a silk screen layer which are adhered together with adhesive and heat. Although some circuit boards are either single-sided, double-sided, or multi-layered, rigid PCBs may be any of these depending on the needs. However, once made, they cannot be modified or changed.

Rigid PCBs are used in GPS equipment, computer, laptops, tablets, mobile phones, X-rays, heart monitors, CAT scans, MRI systems, temperature sensors, control tower instrumentation, etc.

Advantages of Rigid PCBs

Cost-effective

Ease of diagnostics & repair

Low electronic noise

Ability to absorb vibrations

Compact

Lightweight

Flex PCBs

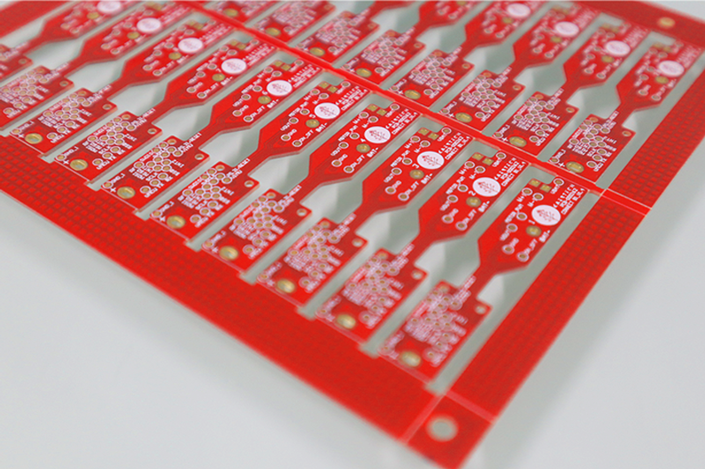

A flexible printed circuit board is made up of many printed circuits and components that are arranged on a flexible substrate. Flexible PCBs are commonly made from polyamide, PEEK (Polyether ether ketone), or a transparent conductive polyester film. Flex circuit boards, flex PCBs, flex circuits, and versatile printed circuits are other names for these circuit boards. These printed circuit boards are made using the same components as rigid printed circuit boards. The main distinction is that the board is designed to flex to the desired form throughout the application. These PCBs are available in single-sided, double-sided, and multilayer configurations. This contributes to a reduction in the complexity of the unit assembly.

Flex PCBs are used in organic light emitting diode (OLED) fabrication, LCD fabrication, flex solar cell, automotive industries, cellular telephones, cameras, and complex electronics products such as laptop computers.

Advantages of Flex PCBs

Save space

Eliminate connectors

Thermal management

Increase reliability and repeatability

Provide uniform electrical characteristics for high-speed circuitry

Suitable for applications where high signal trace density is needed

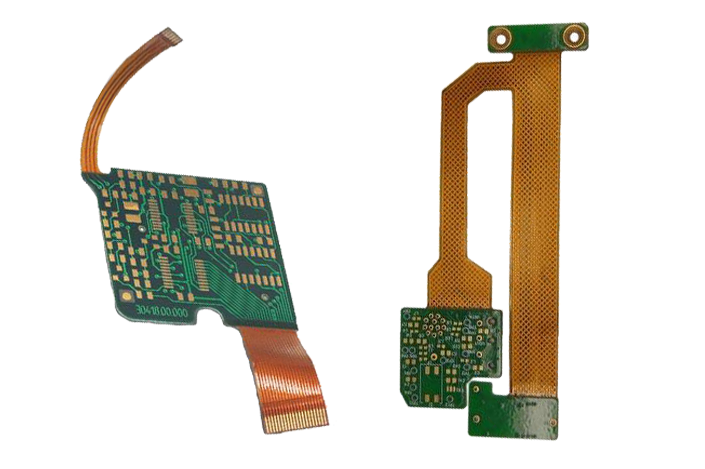

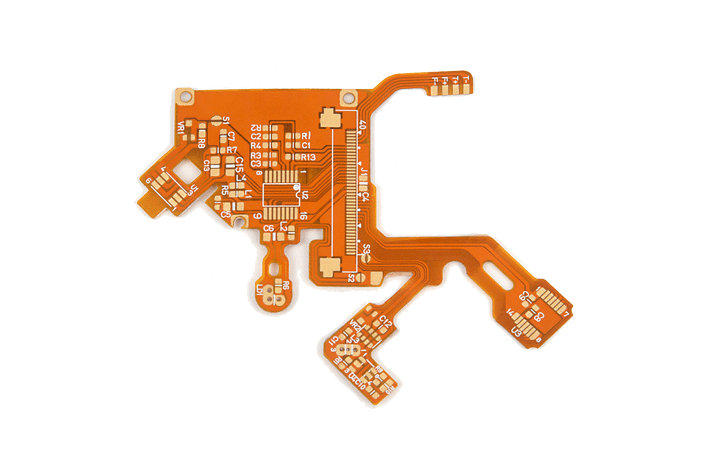

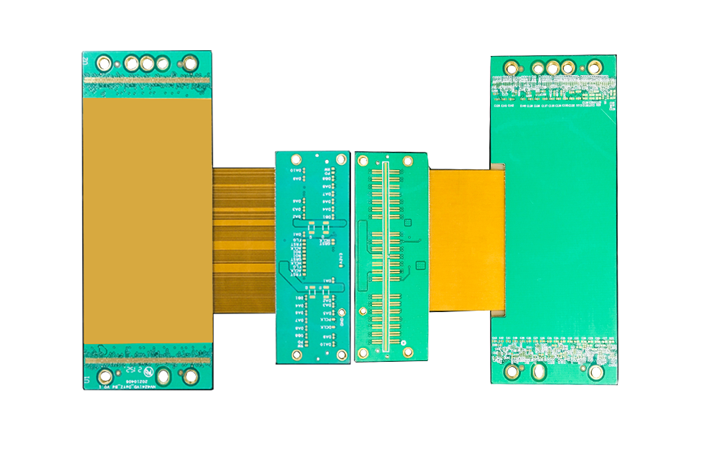

Rigid-Flex PCBs

A Rigid-Flex PCB is a hybrid circuit board that combines elements from both flexible and rigid circuit boards, resulting in a board that can be folded or continuously flexed and is typically shaped into a flexed shape or curve during the manufacturing process. The flexible portion of the board is typically used for interconnections between rigid boards, allowing for narrower conductor lines that take up less room, resulting in smaller boards. Using flexible PCBs for interconnections often removes the need for connectors, which are bulky and cumbersome, making rigid-flex printed circuit boards much lighter. Rigid-Flex PCB designs are a little more complicated since these boards are constructed in 3D, allowing the board to be folded or twisted to produce the desired shape for the product. Designing a board in 3D allows for greater spatial performance, which can then be used in special cases where space and weight reduction are needed, such as in medical devices.

Rigid-flex boards can be designed in a compact manner, and their lightweight nature makes them an excellent option for a wide range of applications in the aerospace, medical, and consumer electronics fields.

Advantages of Rigid-Flex PCBs

360-degree bendability

Reduced space requirement through 3D ability

Shock resistance

Increased reliability

Light weight

Fewer solder joints assure higher connection reliability

Conclusion

While choosing a PCB manufacturing companies think about cost optimization, adequate material usage, delivery time, and more.PCBpartner is your go to partner.

Variety of PCB Material

We can provide up to 54 layers during PCB manufacturing. We also support FR-4 with different tg (135,150,170), CTI 600 (Halogen free) PCB material, Aluminum base PCB, Flexible PCB, Rigid-Flexible PCB, Rogers, and many more materials. Whatever material you need, we can deliver.

Special PCB Specifications:

We have regular PCB production for these special PCB specifications

● Impedance control

● Custom layer stackup

● 1-3 oz copper thickness for outer/inner layers

● Hard gold, ENEPIG, OSP surface finish

● Two different solder mask color on a PCB

● Edge connector plating

● Edge plating

● Via filled with aluminum/resin

● And more…

Fast Lead Time

Turnaround is quick as prototypes take as little as 24 hours to produce, with direct pickup service at our warehouse. We partner with DHL and Fedex for this to make sure you get your PCB in the shortest time possible. We also offer express production options for small and medium sized batches to get your boards EVEN quicker.

Quality Control

After 20 years, we have built a strict standard of quality – our quality control teams ensure all PCBs pass the AOI and E-test 100%.

Technical Support

We have an experienced PCB manufacturing, engineering team to help you detect potential mistakes in your gerber files. We also use – and have used for 15+ years – a reliable software, iPCB, to detect mistakes.

Excellent Customer Service Team

We have a passionate (and patient!) customer service team to help you solve any problems while ordering, handle engineering questions, or answer any after-sales service request. We will respond to you within 1 working day, that’s our customer service guarantee.

Flexible Payment Term

If you have a large amount of PCB to order every month and want to work with us for AMS 30 payment, we are happy to sign an agreement with you.