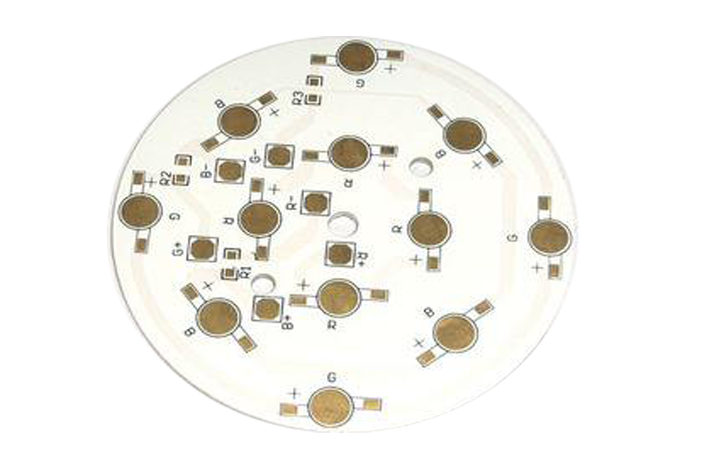

Aluminum PCB Board For LED

July 25, 2022

Aluminum PCB is one type of metal-core printed circuit board (MCPCB), widely used in the LED lighting industry.

Aluminum PCB consists of a dielectric metal base with a bonded copper circuit layer to create superior heat transfer to help cool components while eliminating problems associated with managing fragile ceramics.

Applications of Aluminum PCB:

General lighting applications (Streetlight, Flashlight, Spotlight, etc.)

Backlight unit applications

System automotive LED applications

Power converters: telecom, high voltage regulator, power supplies

Hybrid/electric motor control applications

Photovoltaic

What are the Different Types of Aluminum PCBs?

As said earlier, selecting the type of aluminum circuit board depends largely on the application for which it is used. There are three main types of aluminum PCBs as follows:

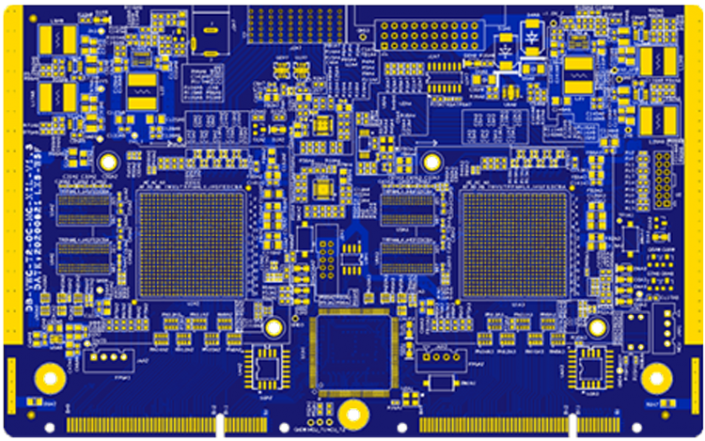

1. Through-hole Aluminum PCBs

In the through-hole aluminum circuit boards, the aluminum is pre-drilled. After that, a dielectric is backfilled into the hole.

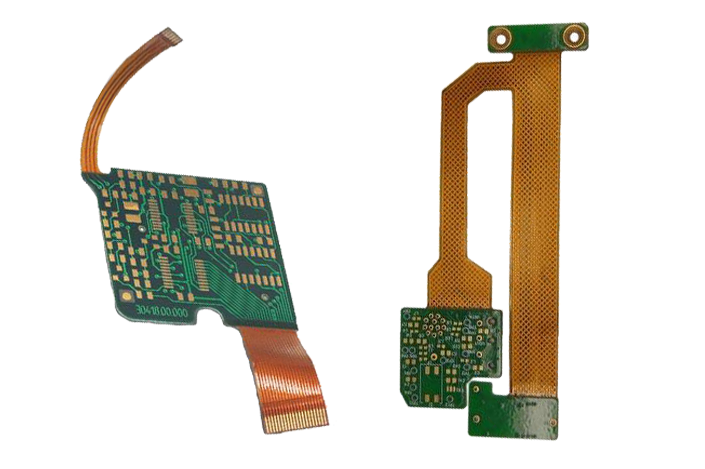

2. Flexible Aluminum PCBs

In these PCBs, flexible dielectrics are used, which provide a high level of flexibility, thermal conductivity, and electrical insulation. When these dielectrics are used with aluminum material, the product thus formed is highly flexible and can be formed in different shapes. This helps eliminate costly connectors and fixtures.

3. Hybrid Aluminum PCBs

These types of aluminum PCBs are generally used in RF applications and are known to provide better thermal performance when used in a standard FR4 product.

Why is Aluminium Used in Circuit Boards?

Aluminum can actually transfer heat away from vital components, thus minimizing the harmful effect it could have on the circuit board.

Higher durability: Aluminum provides strength and durability to a product that ceramic or fiberglass bases cannot.

Aluminum PCB Advantage:

- Improving product durability

- Power density increase

- Increase thermal efficiency

- Reduce the number of interconnects

- Lower junction temperature

- Reduce PCB size

- Eliminate old hardware

- Reduce the workforce required for assembly

- Various shapes and sizes

- Minimize thermal impedance

If you are looking for Aluminum PCB Manufacturer, PCBpartner has rich experience in manufacturing Aluminium PCBs with high thermal conductivity, we offer first-class service and extensive high-tech options.

Advantages of KINJI Aluminum PCBs

- Low Cost

- Environmentally Friendly

- Heat Dissipation

- Higher Durability

- Lightweight

Please keep us informed of any interests!

KINJI cares every your order even 1 piece!