pcb without silkscreen how to Assemble

July 5, 2022

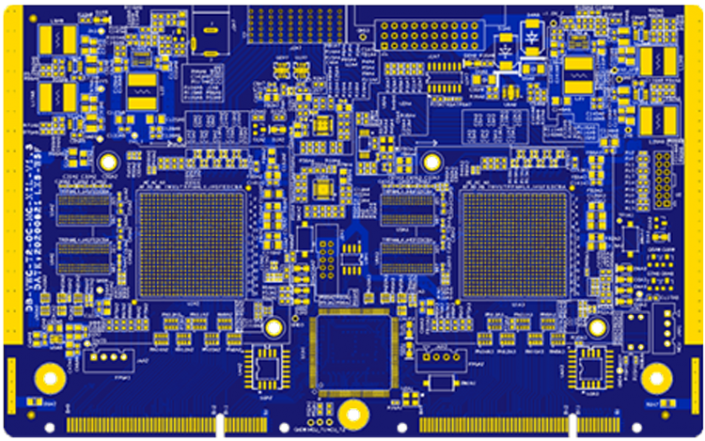

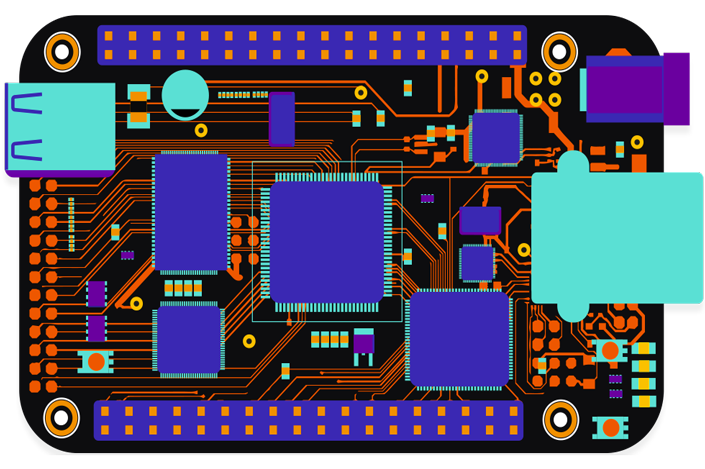

The silkscreen layer is the top layer of the PCB and serves as a reference indicator for placing components on the PCB. which can help users during the assembly. It is used to mark component values, part numbers, test points, polarity, etc.

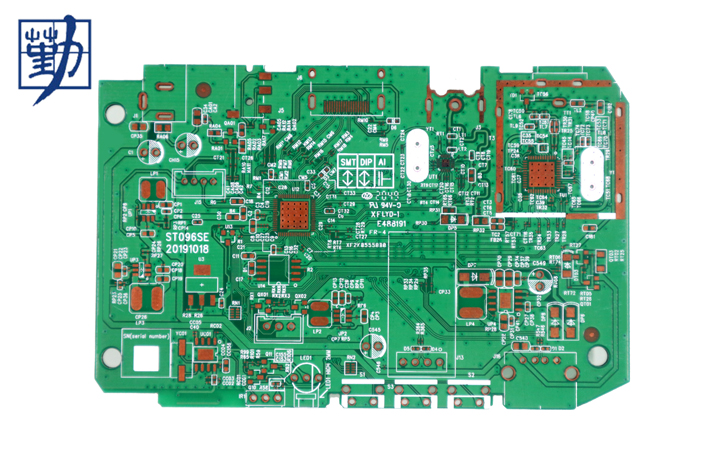

The graphics and text on printed circuit board is usually printed with a permanent non-conductive epoxy ink. The color is typically white, although other colors are also available.

What Information Does a Silkscreen Provide?

A silkscreen may not have any role in the functioning of a PCB; however, it is valued for the information that it delivers. For instance, it will help anyone to:

Understand the warning symbols

Polarity of parts

Identify the test points

Locate the parts through reference designators

Identify the numbers that are unique to the printed circuit board.

Identify manufacturer marks, version numbers, and so on

Methods of Silk Screen Printing

1. Manual Screen Printing:

This is done for PCBs when the registration tolerance is 0. 005 “or line widths are greater than 0. 007”. Manual screen printing is performed using a stencil comprising text and traces. The traces are made using nylon. The ink is directed through the stencil on to the layer or laminate. Next, the ink is cured in the baking oven. This is one of the easiest ways to create a silkscreen layer. and it supports large text size, That will take years to perfect.

2. Liquid Photo Imaging (LPI):

This method is used for screen printing the lines that are greater than 4 mil. The process of LPI is almost the same as the solder mask application. However, in this method, the laminate is coated with epoxy, and then it is brought under the UV light. The board is cured and developed after it. This method ensures higher accuracy than manual screen printing.

LPI uses white color, and it requires more ink than the other two types of silk screen printing. The setup time for this type of printing is high.

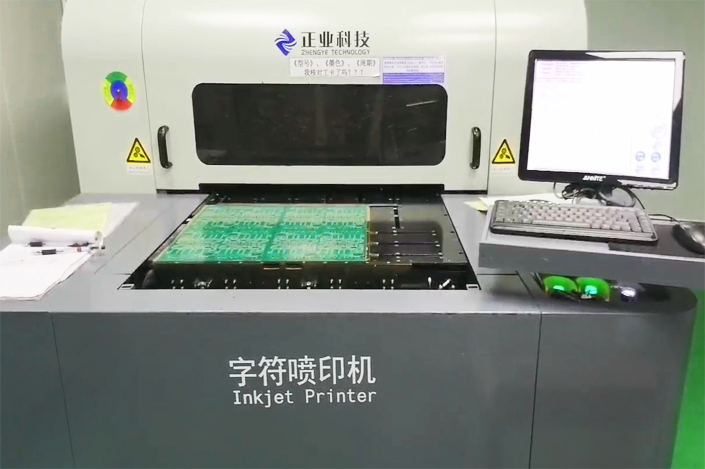

3. Direct Legend Printing (DLP):

This is one of the most expensive processes among the other three. During this process, inkjet projector and acrylic inks are used. The ink is applied to the PCB using the CAD software. The ink is then exposed to the UV light. The acrylic link is not suited for the PCBs that may have silver finishes.

Factors to Keep in Mind When Designing Silk Screen for Your PCB

Do you know the silkscreen contributes to 12-15% of the total PCB costs? The text design includes character width, height, thickness, spacing, and positioning. The cost of ink will depend on the method of silkscreen printing you have opted for. Epoxy ink is used in manual screen printing, and acrylic ink is used for the DLP. The color and properties of the ink are the color contributing factor.

The following are a few things to consider when designing the PCB with a silkscreen legend.

Therefore, when you choose silkscreen for your PCB, you must make the right choice. Knowing the importance of silkscreen printed PCB, it is important that you source it from a trusted manufacturer like PCBPartner. The company provides the PCB in diverse specifications.

You have to try to limit the silkscreen to one side. This will help you cut costs in half. Many PCB assembly services charge for double-sided PCB printing.

Use standard colors and large shapes to make the silkscreen stand out. You can also check if the manufacturer provides any special types of ink.

Direct Legend Printing (DLP) and Liquid Photo Imaging (LPI) more are expensive than the rest because their setup requires a higher investment.

I don’t want silkscreen on my PCBs, how can I proceed with a PCB Assembly order?

For Seeed Fusion PCB Assembly (PCBA) orders, we need to know where to place the components. If you do not want silkscreen on the finished boards, please provide another means of identifying the location and orientation of the components. This can be a PDF of the silkscreen and other layers. Please include this in your PCB file upload when placing the order along with the other manufacturing files. If we cannot work out the placement then we will contact you directly for confirmation which may cause delays to your order.

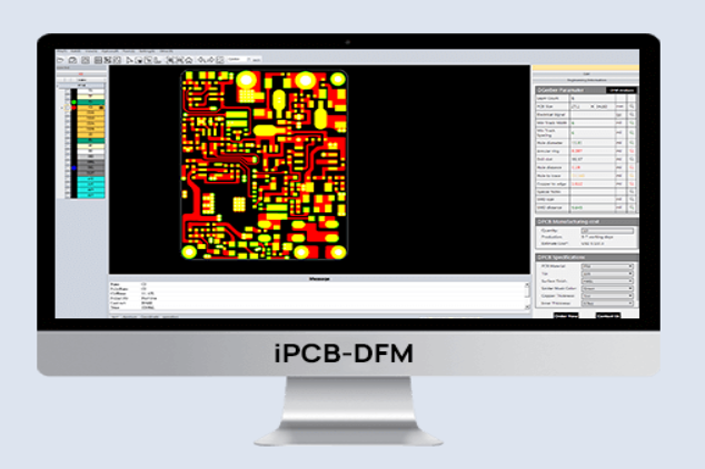

Your silkscreen on your PCB in PCBPartner

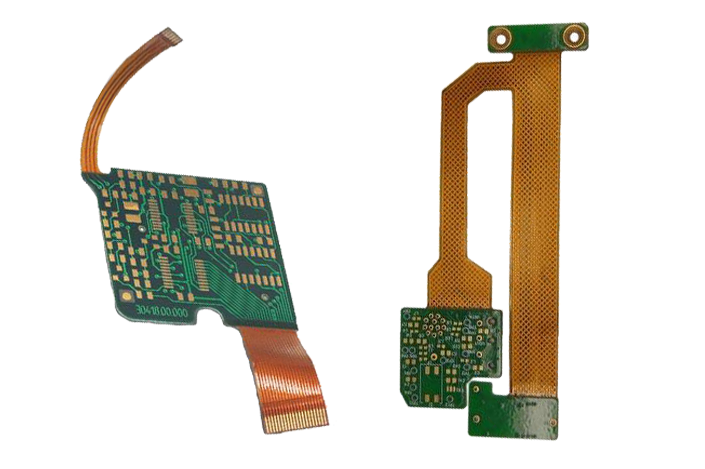

With over 20 years as an industry leader, PCBPartner is one of the most experienced china pcb manufacturer. highly specialized not only in quick-turn PCB prototype ,but also medium and small volume PCB fabrication. We can provide silkscreen on your PCBs for you, and we will try our best to meet the demands of silkscreen.

If you have any questions, please feel free to contact us with services@pcbpartner.com, we will be happy to help you.