Sorry, no sales person is available right now to take your call. Pls leave a message and we will reply to you via email as soon as possible.

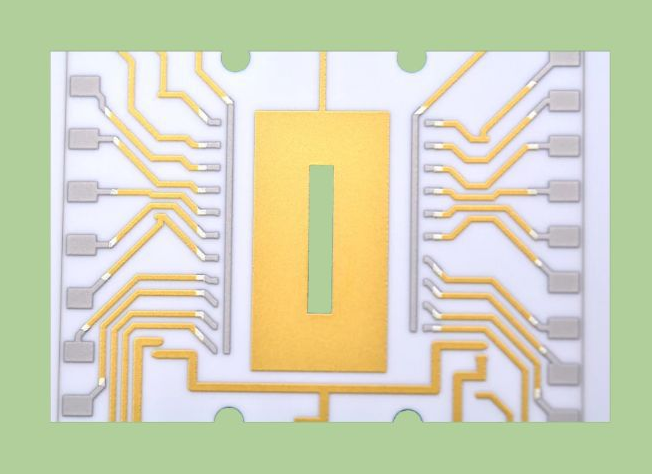

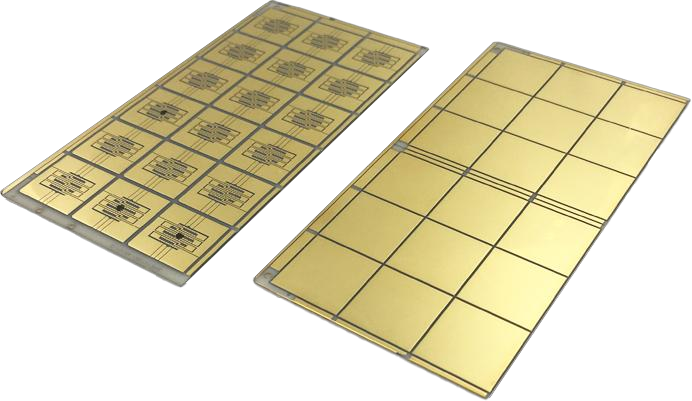

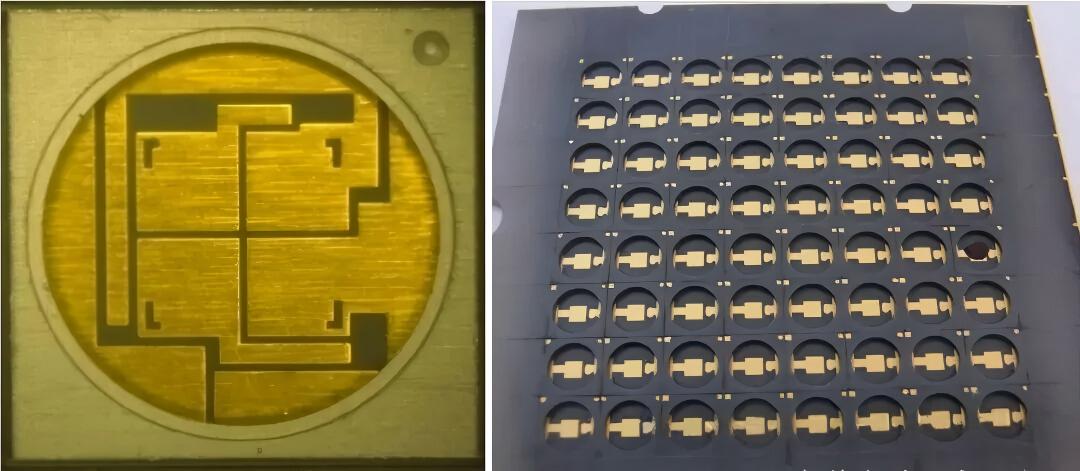

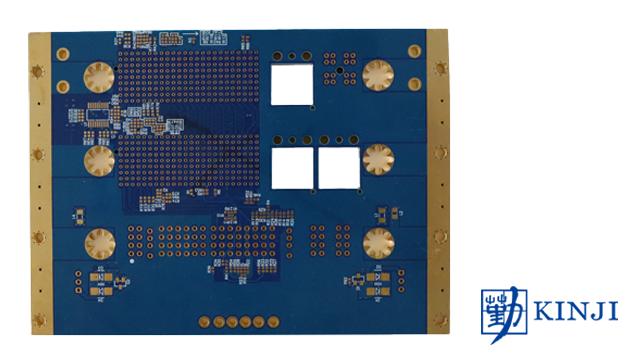

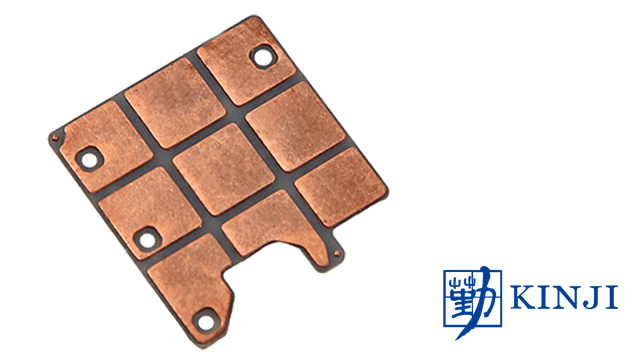

Ceramic substrates have become the cornerstone of high-power, high-density electronic packaging due to their excellent insulation, thermal conductivity, and mechanical stability. Metallization, the key process of forming conductive layers on ceramic surfaces, directly determines the electrical connectivity, thermal management, and long-term reliability of PCB ceramic substrates.

The distinctions are significant, rooted in their superior material properties and specialized applications. Let’s break down everything you need to know about 99 alumina ceramic substrates, including their background, technical challenges, real-world uses, and manufacturing breakthroughs.

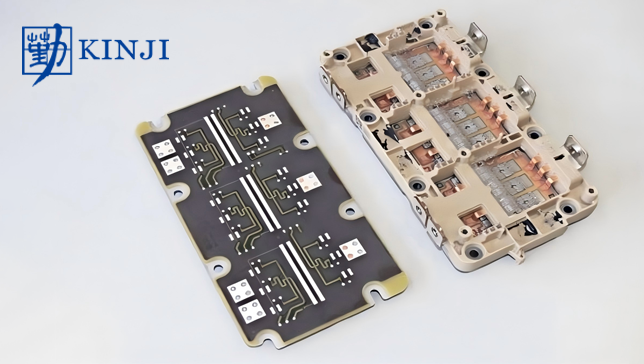

Ceramic substrates (also called ceramic circuit boards) are core components for electronic packaging, integrating electrical interconnection, mechanical support and heat dissipation.

Master Heavy Copper PCB design for high-power electronics. Learn guidelines for current capacity, thermal management, and DFM to ensure reliable manufacturing.

Optimizing embedded power modules requires managing PCB warpage. The article analyzes thermal interface risks, structural solutions, and reliability trade-offs.

Discover why AMB ceramic substrates outperform DBC in thermal reliability, bonding strength, and material flexibility for EVs, solar, and rail power systems.