Sorry, no sales person is available right now to take your call. Pls leave a message and we will reply to you via email as soon as possible.

How to select high-frequency PCB and high-speed PCB materials

With the increasing operating speeds of microprocessors and signal conversion/transmission devices, the operating speed of digital circuits has reached a higher level: 100Gbps. Using conventional PCB materials can no longer meet high-speed signal requirements, and the selection of circuit board materials will determine product performance.

Material Selection Considerations

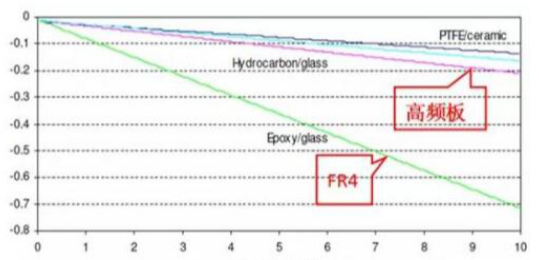

Choosing PCB materials requires balancing design requirements, manufacturability, and cost. Design requirements encompass both electrical and structural reliability aspects. Material selection becomes particularly critical for designing ultra-high-speed PCBs (frequencies above GHz). For example, the commonly used FR-4 material exhibits significant dielectric loss (Df) at several GHz frequencies, making it unsuitable.

Loss Characteristics of Different Materials

A 10Gb/s high-speed digital signal is a square wave, which can be decomposed into superimposed sinusoidal waves of different frequencies. Thus, a 10Gb/s signal includes multiple frequency components: a 5GHz fundamental wave, 3rd-order 15GHz, 5th-order 25GHz, and 7th-order 35GHz signals. Maintaining the integrity of digital signals, steep rising/falling edges, and low-loss/low-distortion transmission of high-frequency harmonics (which enter the microwave frequency range) are similar to the requirements for RF/microwave circuits. Consequently, material selection for high-speed digital PCBs shares many similarities with RF/microwave circuit needs.

Time Domain vs. Frequency Domain

In practical engineering, selecting high-frequency materials may seem straightforward but involves numerous considerations. This article aims to help PCB design engineers and high-speed project leaders understand material properties, including electrical performance, thermal stability, and reliability. By optimizing layer stackup design, engineers can develop products with high reliability and manufacturability while balancing all critical factors.

Key Factors for Material Selection

- Manufacturability:Multi-lamination compatibility, temperature tolerance, CAF resistance, thermal/mechanical durability (reliability), and flame-retardant ratings.

- Performance Alignment with Product Requirements:Low loss, stable Dk/Df parameters, low dispersion, minimal variation with frequency/environmental changes, tight thickness/glue content tolerances (for impedance control), and low-profile copper foil for long traces.Simulation is critical in early design stages. The Xingsen Technology-Agilent (High-Speed/RF) Joint Laboratory addresses simulation-test mismatches through extensive closed-loop validation, ensuring alignment between simulations and measurements.

- Material Availability:Many high-frequency materials have long lead times (up to 2-3 months). Except for common materials like RO4350, most require custom procurement. Early communication with suppliers is essential.

- Cost Sensitivity:Determine whether the product is cost-sensitive (consumer applications) or prioritizes performance (communications, medical, industrial, military).

- Regulatory Compliance:Adherence to environmental regulations (e.g., RoHS, halogen-free requirements) across target markets.

Speed-Driven Material Selection

The operating speed of high-speed digital circuits is the primary factor in PCB material selection. Higher speeds demand lower Df values:

- Df 0.01–0.005: Suitable for ≤10Gb/s

- Df 0.005–0.003: Suitable for ≤25Gb/s

- Df ≤0.0015: Suitable for ≥50Gb/s

Common High-Speed Materials

- Rogers: RO4003, RO3003, RO4350, RO5880

- TUC: Tuc862, 872SLK, 883, 933

- Panasonic: Megtron4, Megtron6

- Isola: FR408HR, IS620, IS680

- Nelco: N4000-13, N4000-13EPSI

- Domestic Suppliers: Dongguan Shengyi, Taizhou Wangling, Taixing Microwave, etc.

This translation preserves technical accuracy while optimizing readability for engineers and industry professionals.