Sorry, no sales person is available right now to take your call. Pls leave a message and we will reply to you via email as soon as possible.

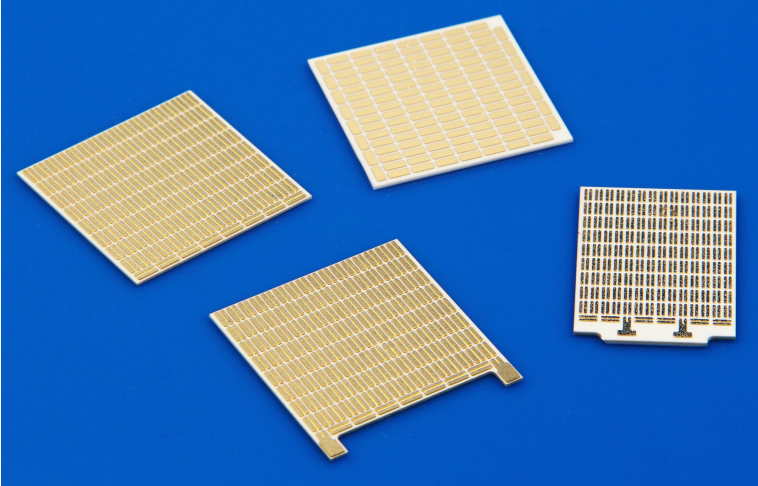

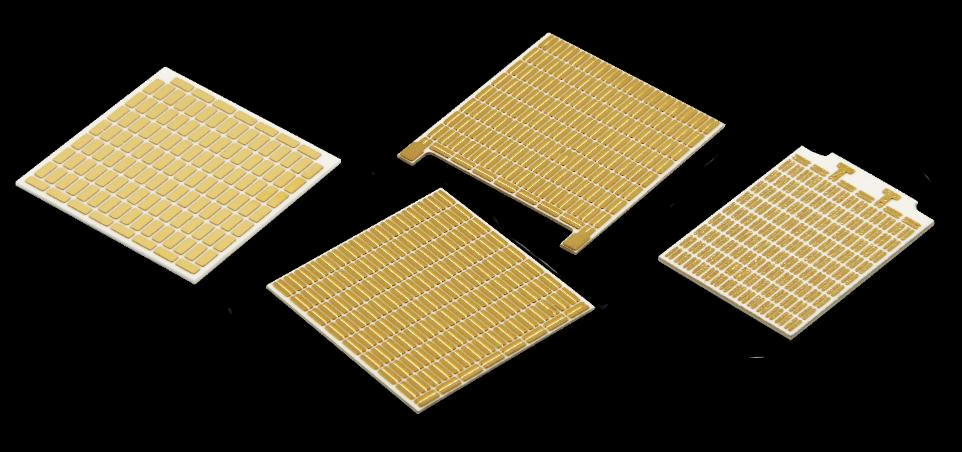

Direct Bonded Copper (DBC) Ceramic Substrate

Direct Bonded Copper (DBC) substrate is a process in which highly insulating ceramic base materials, such as alumina (Al₂O₃) or zirconia-toughened alumina (ZTA), are bonded with copper metal on one or both sides. The assembly is then sintered at temperatures between 1065°C and 1085°C. During this high-temperature process, the copper oxidizes and diffuses, forming a eutectic melt with the ceramic surface, thereby creating a strong bond between the copper and the ceramic substrate, resulting in a ceramic-metal composite base.

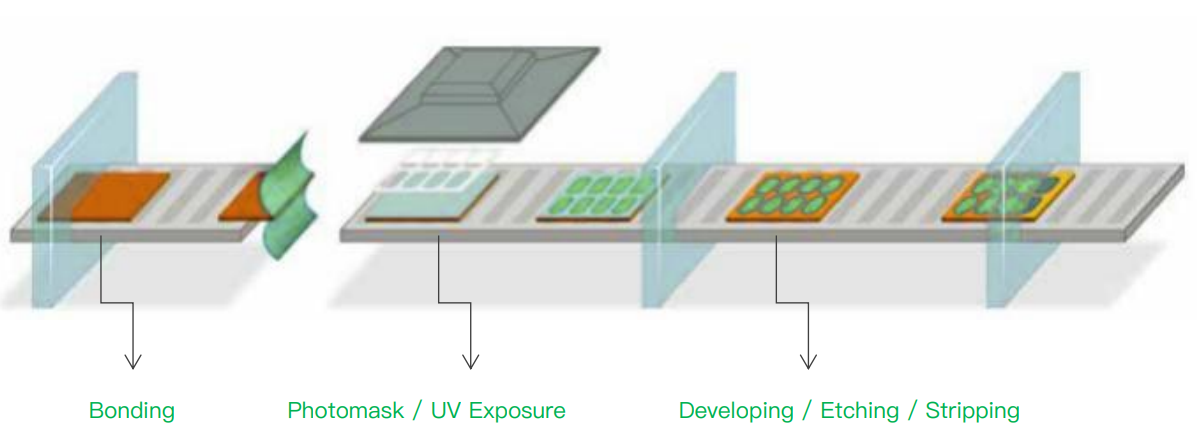

Patterns are then transferred onto the substrate using photolithography (yellow light process), followed by circuit formation through vacuum etching. Solder resist is applied using automatic printing equipment, and surface finishing and laser shaping are subsequently carried out.

Applied Area

• Automotive: ABS, Power Steering, DC/DC Converter, LED Lighting, Ignition Control

• Power Electronics: IGBT, MOSFET, Thyristor Module, Solid-state Relay, Diode, Power Transistors

• Home Appliance: Air Conditioner, Peltier Cooler

• Industrial: LED Displays, Welding Machine

• Aerospace: Laser, Power Supply for Satellites and Aircrafts

• Environmental Technology: Local Power Generation, Electric Vehicle, Traction Control System, Photovoltaic Units, Wind Power

• PC/IT: Power S

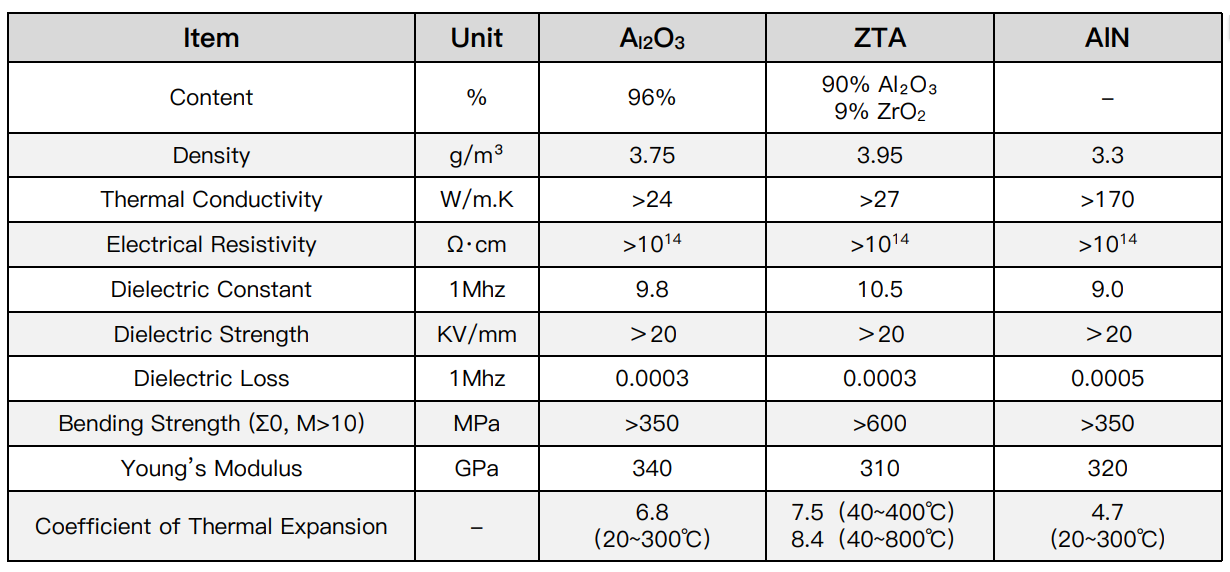

Ceramic Materials Properties

1. High Thermal Conductivity

2. Low Thermal Expansion

3. High Strength

4. High Wettability for Solder

Patterning Process

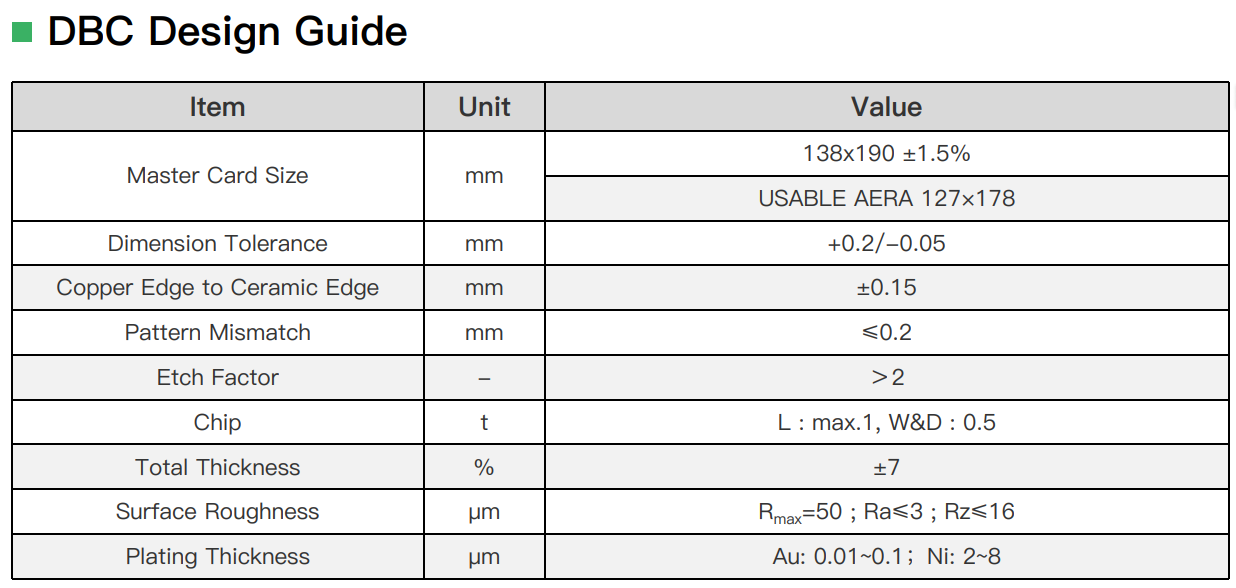

Material Specification & Properties

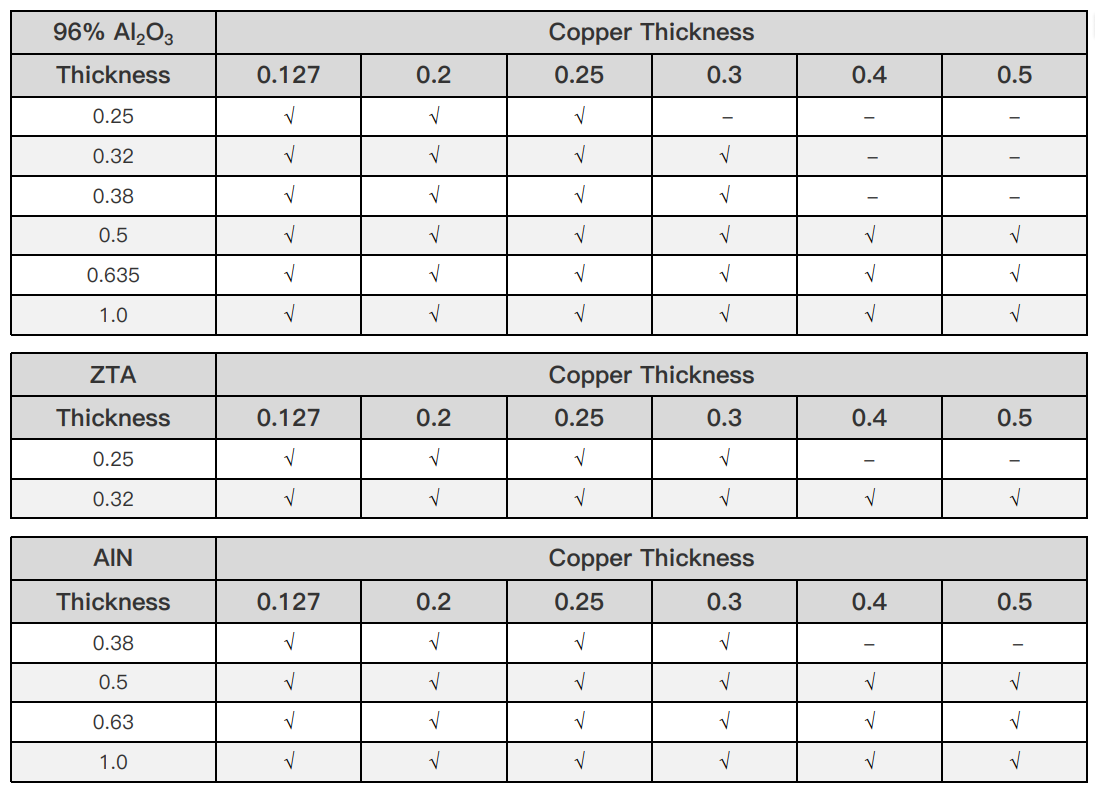

Available Material Thickness and Combination

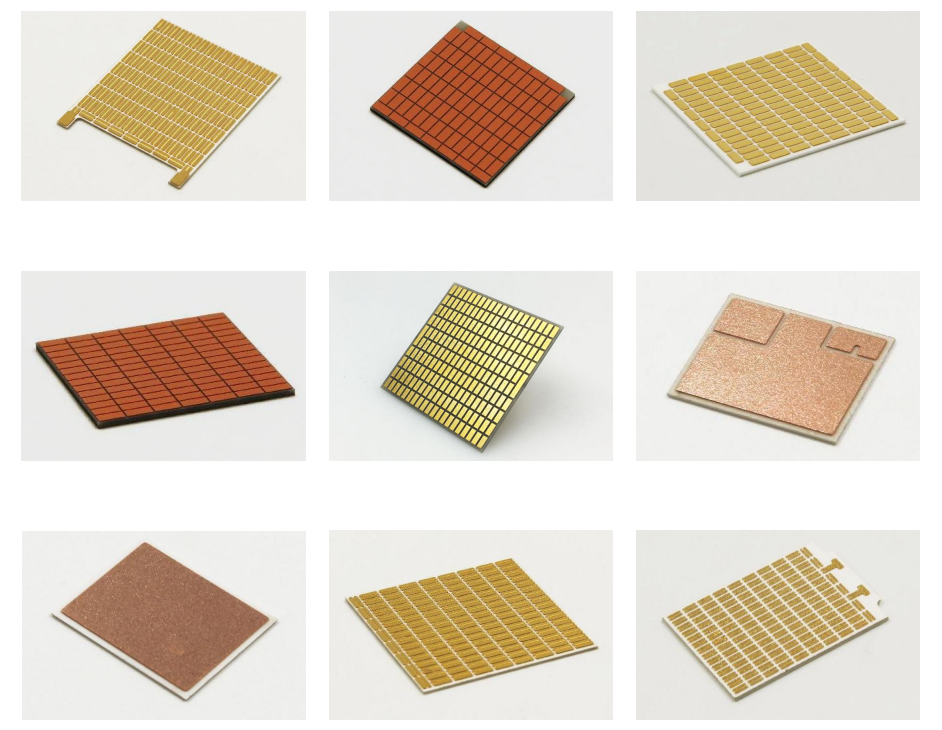

Show Case

upply, UPS System