Sorry, no sales person is available right now to take your call. Pls leave a message and we will reply to you via email as soon as possible.

DPC Ceramic Substrate (Direct Plated Copper)

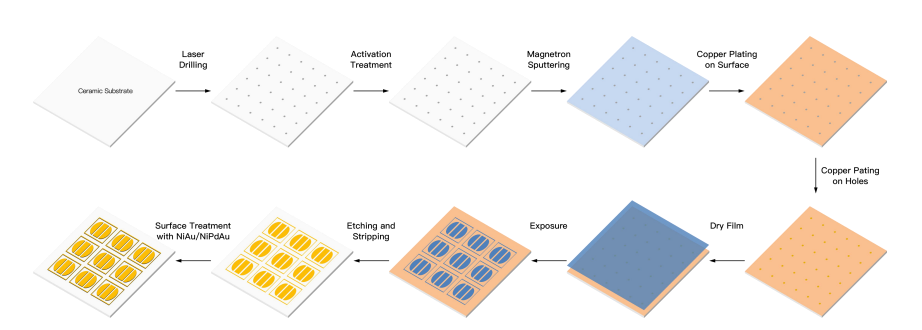

DPC is a newest development in the field of Ceramic Substrate PCBs, by magnetron sputtering technology to deposit a metal layer (Ti/Cu target) on the surface of the ceramic substrate which result in copper thickness’ ranging from 10um to 130um, and then photolithography to form circuit patterns, electroplating is used to fill in the gaps and thicken the metal circuit layer, and the solderability and oxidation resistance of the substrate is improved through surface treatment, finally remove the dry film, and etch the seed layer to complete the substrate.

Features

1. High thermal stability and excellent electrical conductivity

2. Excellent mechanical stability, good adhesion

3. High operating temperatures

4. Excellent electrical insulation

5. Good heat spreading

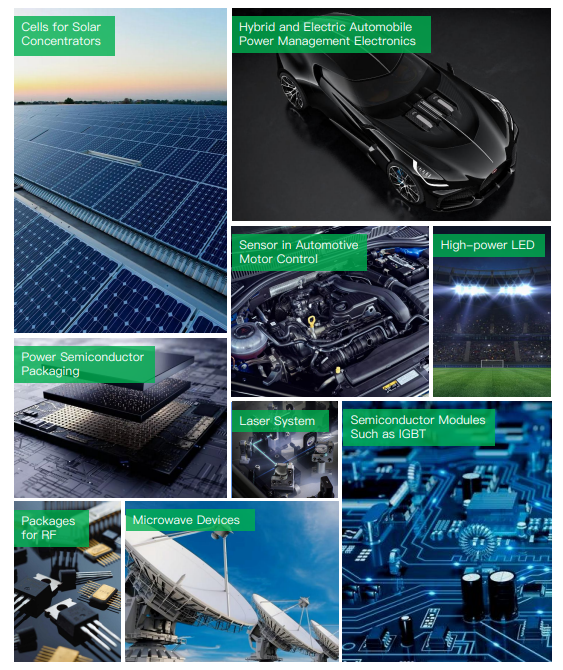

Applications

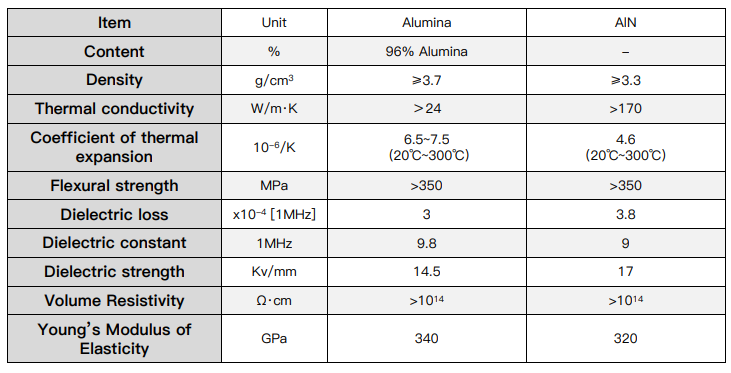

Ceramic Materials Properties

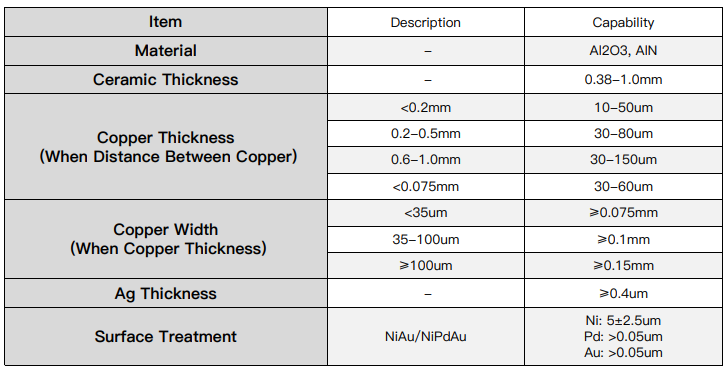

Capability

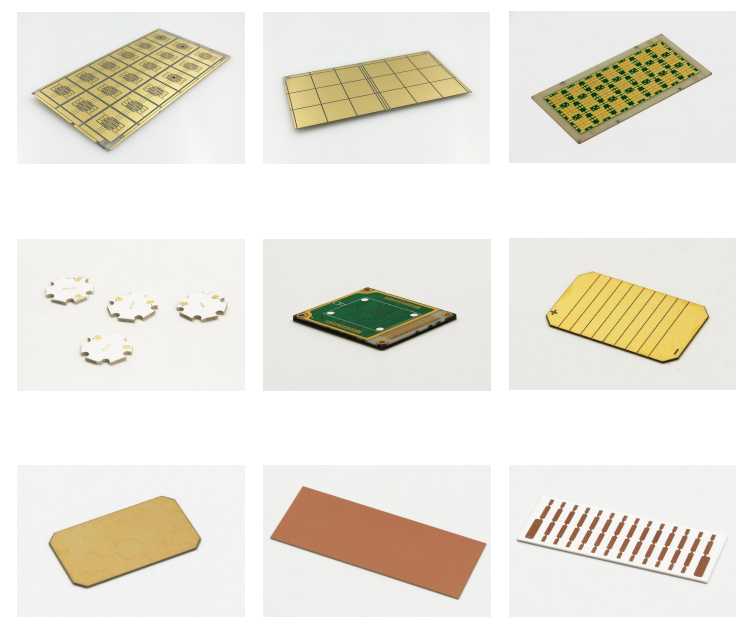

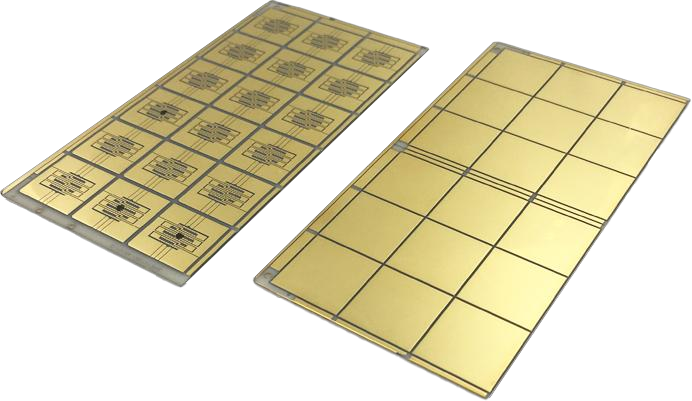

Show Case