Sorry, no sales person is available right now to take your call. Pls leave a message and we will reply to you via email as soon as possible.

Ceramic Substrates | kinji

Ceramic substrates (also called ceramic circuit boards) are core components for electronic packaging, integrating electrical interconnection, mechanical support and heat dissipation. With excellent thermal conductivity, high temperature resistance, superior mechanical strength and low thermal expansion coefficient, they are widely applied in power semiconductors, automotive electronics, aerospace and other high-end fields. kinji provides two major categories of ceramic substrates to meet diverse application needs: Planar Ceramic Substrates and 3D Ceramic Substrates.

Planar Ceramic Substrates

Tailored for different precision, power and cost requirements, kinji’s planar ceramic substrates cover multiple core technologies, providing reliable solutions for various electronic devices.

Key Product Series & Core Advantages

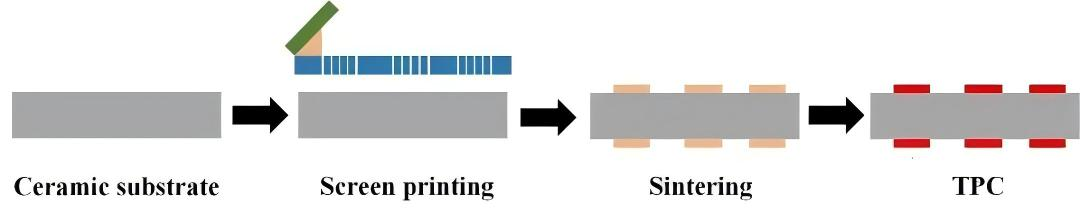

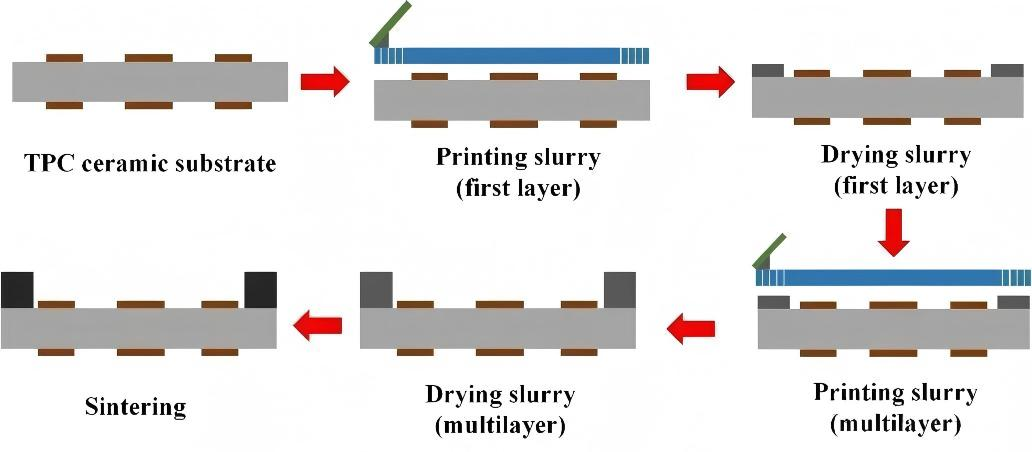

TPC Substrate Preparation Process Flow Chart

| Product Type | Core Advantages | Typical Applications |

| Thin Film Ceramic Substrate (TFC) | High pattern precision (line width/space < 10 μm), thin metal layer (< 1 μm) | Lasers, optical communications, small-current devices |

| Thick Film Printed Ceramic Substrate (TPC) | Simple process, cost-effective, adjustable metal layer thickness (10–20 μm) | Automotive electronics, low-precision high-current devices |

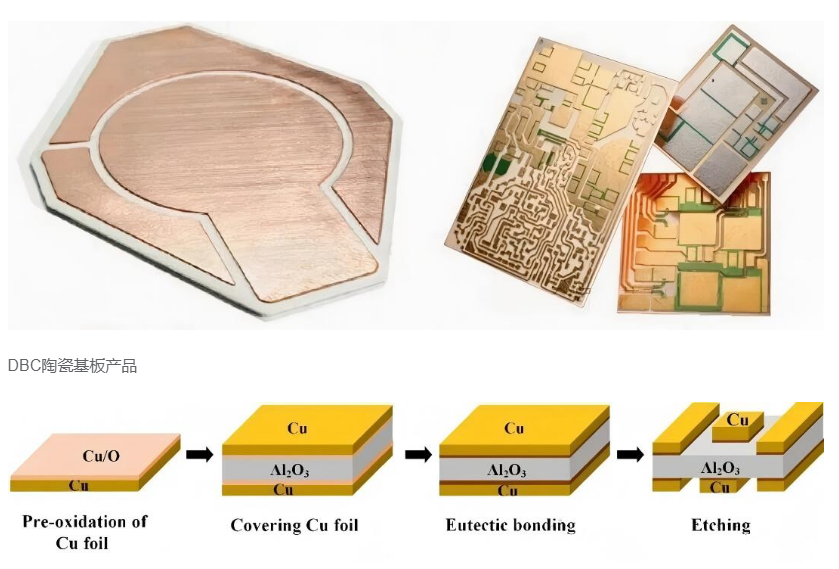

| Direct Bonded Copper Ceramic Substrate (DBC) | Excellent thermal conductivity, high bonding strength, thick copper foil (100–600 μm) | IGBT modules, lasers, concentrated photovoltaics (CPV) |

| Active Metal Brazed Ceramic Substrate (AMB) | Superior bonding strength, excellent thermal cycle performance | Automotive power modules, high-reliability devices |

| Direct Plated Copper Ceramic Substrate (DPC) | High circuit precision, vertical interconnection capability | High-density packaging, small & medium power devices |

| Laser Activated Metallization Ceramic Substrate (LAM) | Flexible design, suitable for local metallization and fine circuits | Customized precision electronic devices |

DBC Ceramic Substrate Preparation Process Flow

3D Ceramic Substrates

Based on planar substrate technology, kinji’s 3D ceramic substrates add cavities, steps and other three-dimensional structures to meet complex packaging integration needs, supporting the miniaturization and high-performance of electronic products.

Key Product Series & Core Advantages

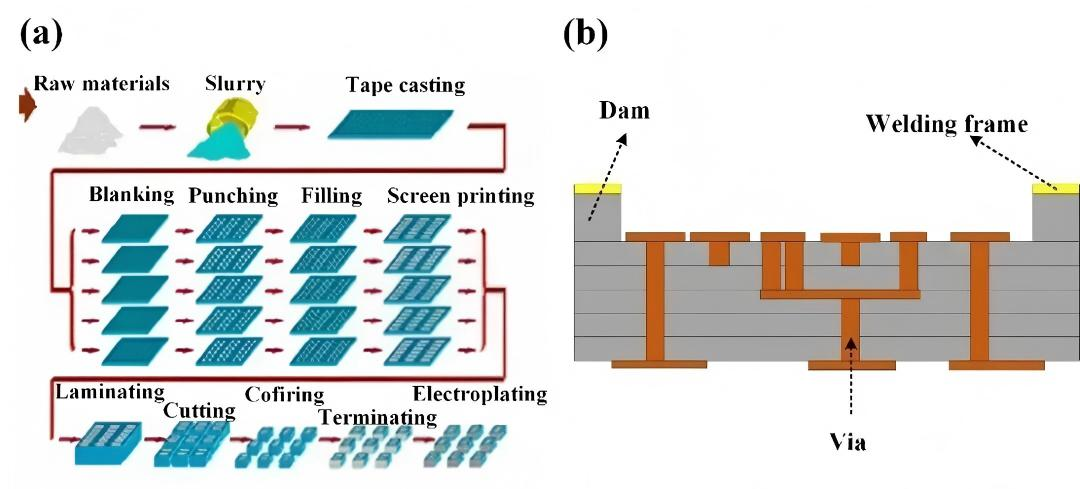

(a) HTCC Ceramic Substrate Preparation Process Flow and (b) Schematic Diagram

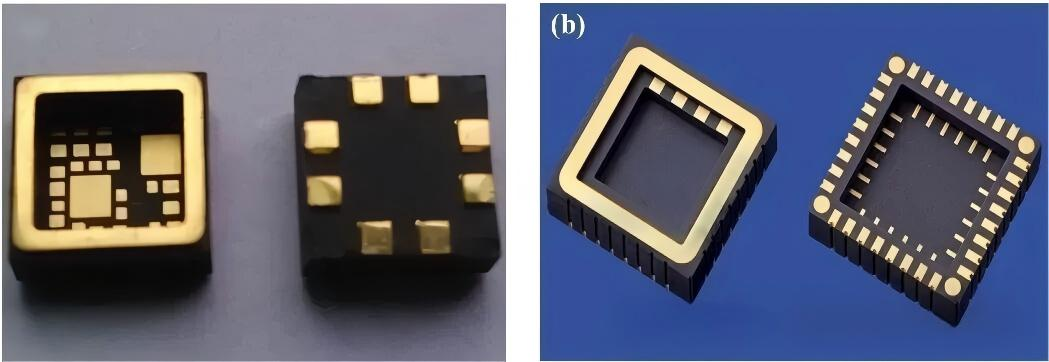

(a) HTCC Ceramic Substrate Products and (b) LTCC Ceramic Substrate Products

| Product Type | Core Advantages | Typical Applications |

| HTCC/LTCC Substrates | HTCC: High mechanical strength & stability; LTCC: Low sintering temp, excellent dielectric properties | Aerospace, military electronics, high-frequency modules |

| Multilayer Sintered 3D Ceramic Substrate (MSC) | Simple process, good thermal expansion matching | Small devices with low precision requirements |

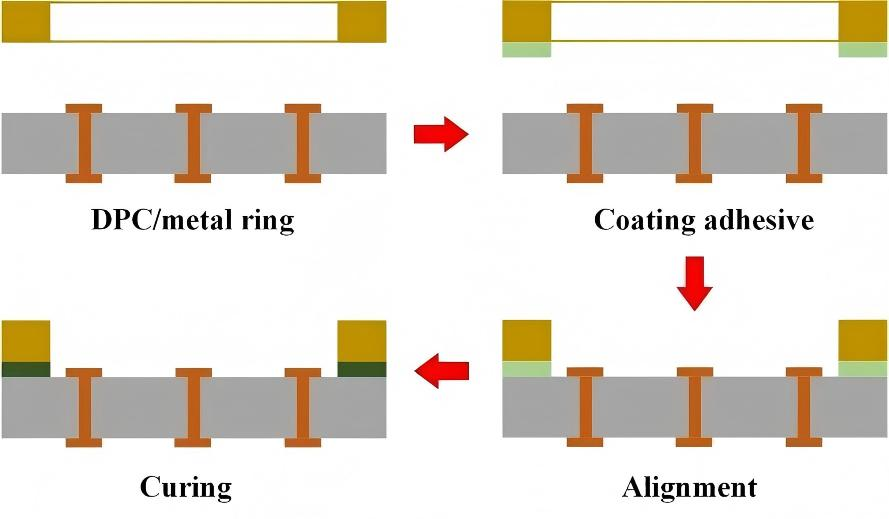

| Direct Adhered 3D Ceramic Substrate (DAC) | Cost-effective, low-temperature bonding, no damage to circuit layers | High-precision devices with low heat dissipation requirements |

| Multilayer Plated Copper 3D Ceramic Substrate (MPC) | High precision, high thermal conductivity, 3D circuit integration | High-density, high-performance electronic packaging |

| Direct Molding 3D Ceramic Substrate (DMC) | Mass production available, suitable for complex structures | Customized 3D packaging components |

MSC Ceramic Substrate Preparation Process Flow

DAC Three-Dimensional Ceramic Substrate Preparation Process Flow

Our Strengths

kinji has rich experience in ceramic substrate R&D and production, mastering core technologies such as DBC, AMB, HTCC/LTCC. We adhere to strict quality control standards, providing customers with high-reliability, high-performance ceramic substrate products. Our solutions are widely recognized in automotive electronics, new energy, aerospace and other fields, supporting global customers to achieve product innovation and upgrade.

For more product details or customized solutions, please contact kinji’s overseas sales team.