Sorry, no sales person is available right now to take your call. Pls leave a message and we will reply to you via email as soon as possible.

Fabrication and Reliability of Si₃N₄ Ceramic Copper‑Clad Substrates

Introduction

Silicon nitride ceramic copper‑clad substrates (Si₃N₄‑AMB‑Cu) are considered ideal materials for power modules in high‑speed railways and electric vehicles due to their high reliability. To break foreign technological monopolies, this study successfully achieved independent fabrication of Si₃N₄‑AMB‑Cu substrates by combining gas‑pressure sintering with active metal brazing (AMB).

Superior Fundamental Properties

The fabricated Si₃N₄ ceramic substrates exhibit outstanding performance: bending strength of 800 MPa, fracture toughness of 8.0 MPa·m¹/², and thermal conductivity of 90 W/(m·K). The copper‑clad substrates achieved a peeling strength of 130 N/cm, indicating robust interfacial bonding.

Reliability Performance

Thermal cycling tests between −45 °C and 150 °C demonstrated reliability far superior to conventional materials:

- Lifetime: 10× longer than AlN‑AMB‑Cu and 100× longer than Al₂O₃‑DBC‑Cu.

- Severe testing: Even under thick copper layers (0.8 mm/0.8 mm), the substrates endured 500 cycles without microcracks, proving exceptional thermal shock resistance.

With the global push toward clean energy and electrification, high‑power electronic devices such as Insulated Gate Bipolar Transistors (IGBTs) are widely applied in rail transit, smart grids, and electric vehicles. Increasing power density imposes stricter requirements on ceramic copper‑clad substrates for heat dissipation and reliability.

Currently, common ceramic substrate materials include Al₂O₃ (alumina), AlN (aluminum nitride), and Si₃N₄ (silicon nitride):

- Al₂O₃‑DBC‑Cu: limited by low thermal conductivity, used in low‑performance scenarios.

- AlN‑AMB‑Cu: excellent thermal conductivity but insufficient mechanical strength, limiting thermal cycling reliability.

- Si₃N₄‑AMB‑Cu: combines high strength, toughness, and thermal stability, offering superior comprehensive reliability.

Compared with AlN and Al₂O₃, Si₃N₄‑AMB‑Cu demonstrates both comparable thermal conductivity and significantly longer service lifetimes, making it highly promising for next‑generation power electronics.

1. Experimental

1.1 Materials and Equipment

- Substrate: domestically produced high‑performance Si₃N₄ ceramic.

- Copper foil: oxygen‑free copper.

- Brazing alloy: Ag‑Cu active metal paste (72Ag‑28Cu with trace active elements).

- Equipment: screen printer (KM‑SY4060A) and vacuum brazing furnace (YLM11‑3020W).

1.2 Fabrication of Si₃N₄‑AMB‑Cu

The Si₃N₄‑AMB‑Cu substrates were fabricated using the Active Metal Brazing (AMB) process:

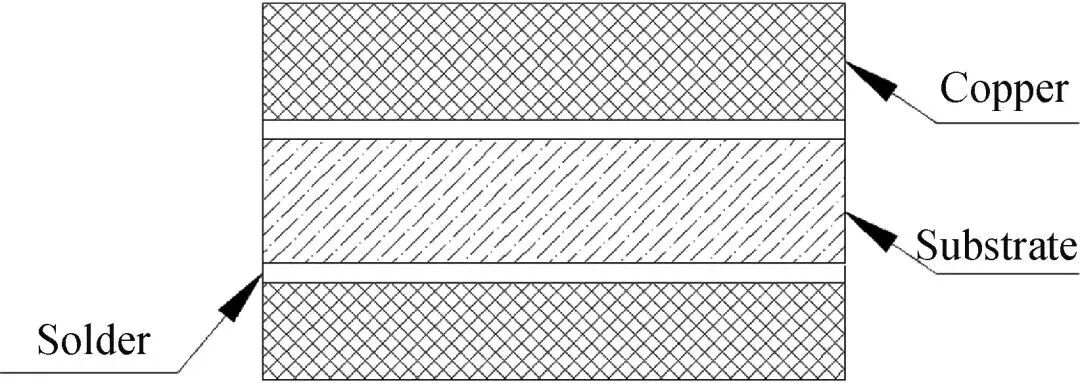

Figure 1. Schematic structure of Si₃N₄‑AMB‑Cu ceramic substrate

- Pre‑treatment: ultrasonic cleaning of Si₃N₄ substrates in distilled water at 70 °C for 1 min, followed by drying.

- Paste coating: uniform application of Ag‑Cu brazing paste on both sides using screen printing, solvent evaporation at 80 °C.

- Copper cladding and brazing: oxygen‑free copper foils laminated on both sides, brazed at 800 °C under 10⁻³ Pa vacuum for 10 min, yielding Si₃N₄‑AMB‑Cu samples.

2. Results and Discussion

2.1 Material Properties

2.1 Mechanical Properties2.1.1 Mechanical Properties

Ceramic substrates serve as both electrical insulators and chip carriers in power devices, and their mechanical properties directly determine service lifetime.

- Bending strength: Si₃N₄ reaches 800 MPa, nearly twice that of AlN (450 MPa) and Al₂O₃ (400 MPa).

- Thermal expansion coefficient: 2.4 ppm/K, closely matched to silicon (~2.5 ppm/K), significantly lower than AlN (4.6 ppm/K) and Al₂O₃ (6.7 ppm/K).

- Fracture toughness: 8.0 MPa·m¹/², over 2× higher than AlN and Al₂O₃ (3.0 MPa·m¹/²).

Table 1. Mechanical properties of Si₃N₄, AlN, and Al₂O₃ ceramic materials

| Basic property | Si₃N₄(a) | Si₃N₄(b) | AlN(b) | Al2O3(b) |

|---|---|---|---|---|

| Density/(g/cm3) | 3.22 | 3.22 | 3.26 | 3.75 |

| Bending strength/MPa | 800 | 800 | 450 | 400 |

| Fracture toughness/(MPa·m1/2) | 8.0 | 6.5 | 3.0 | 3.0 |

*Note: (a) is made by Advanced Carbide Ceramics Group in SICCAS; (b) the data is from the website of Maruwa.

2.1.2 Thermal Properties

Heat management is critical for reliability. Although Si₃N₄ thermal conductivity (90 W/(m·K)) is lower than AlN (180 W/(m·K)), reducing substrate thickness compensates for thermal resistance while maintaining mechanical integrity.

Table 2. Thermal properties of Si₃N₄, AlN, and Al₂O₃ ceramic materials

| Basic property | Si₃N₄(a) | Si₃N₄(b) | AlN(b) | Al₂O₃(b) |

|---|---|---|---|---|

| Thermal conductivity/(W/(m·K)) | 90 | 85 | 180 | 24 |

| Thermal expansion coefficient/(10-6 1/K) | 2.4 | 2.6 | 4.6 | 6.7 |

| Specific heat/(J/(kg·K)) | 0.66 | 0.68 | 0.72 | 0.75 |

2.1.3 Electrical Properties

Si₃N₄ substrates exhibit superior insulation strength:

- Breakdown strength: 40 kV/mm (AC/DC), far exceeding AlN and Al₂O₃ (15–20 kV/mm).

- Volume resistivity: 3.7×10¹⁴ Ω·cm, comparable to imported high‑end products.

- Dielectric constant: 6.0 at 1 MHz, lower than AlN (9.0) and Al₂O₃ (9.8).

Table 3. Electrical properties of Si₃N₄, AlN, and Al₂O₃ ceramic materials

| Basic property | Si₃N₄(a) | Si₃N₄(b) | AlN(b) | Al₂O₃(b) |

|---|---|---|---|---|

| Breakdown strength/(kV/mm) (AC) | 40 | 20 | 20 | - |

| Breakdown strength/(kV/mm) (DC) | 40 | 15 | 15 | 15 |

| Theoretical thinnest thickness/mm (6.5 kV) | 0.17 | 0.33 | 0.33 | 0.33 |

| Dielectric constant/(1 MHz) | 6.0 | 9.0 | 9.0 | 9.8 |

| Dielectric loss/10-3(1 MHz) | 0.4 | 0.2 | 0.2 | 0.2 |

| Volume resistivity/(Ω·cm) | 1014 | 1014 | 1014 | 1014 |

2.2 Reliability Evaluation

2.2.1 Peeling Strength

Si₃N₄‑AMB‑Cu achieved 130 N/cm, superior to Al₂O₃‑DBC‑Cu (40 N/cm) and comparable to imported products.

Table 4. Peeling strength of Si₃N₄‑AMB‑Cu compared with AlN and Al₂O₃ substrates

| Basic property | Si₃N₄(a) | Si₃N₄(c) | AlN(b) | Al₂O₃(c) |

|---|---|---|---|---|

| Peeling strength/(N/cm) (Cu) | 130 | >100 | 180 | 40 |

*Note: (a) is made by Advanced Carbide Ceramics Group in SICCAS; (b) is from the Maruwa; (c) the data is from the website of Rogers Corporation.

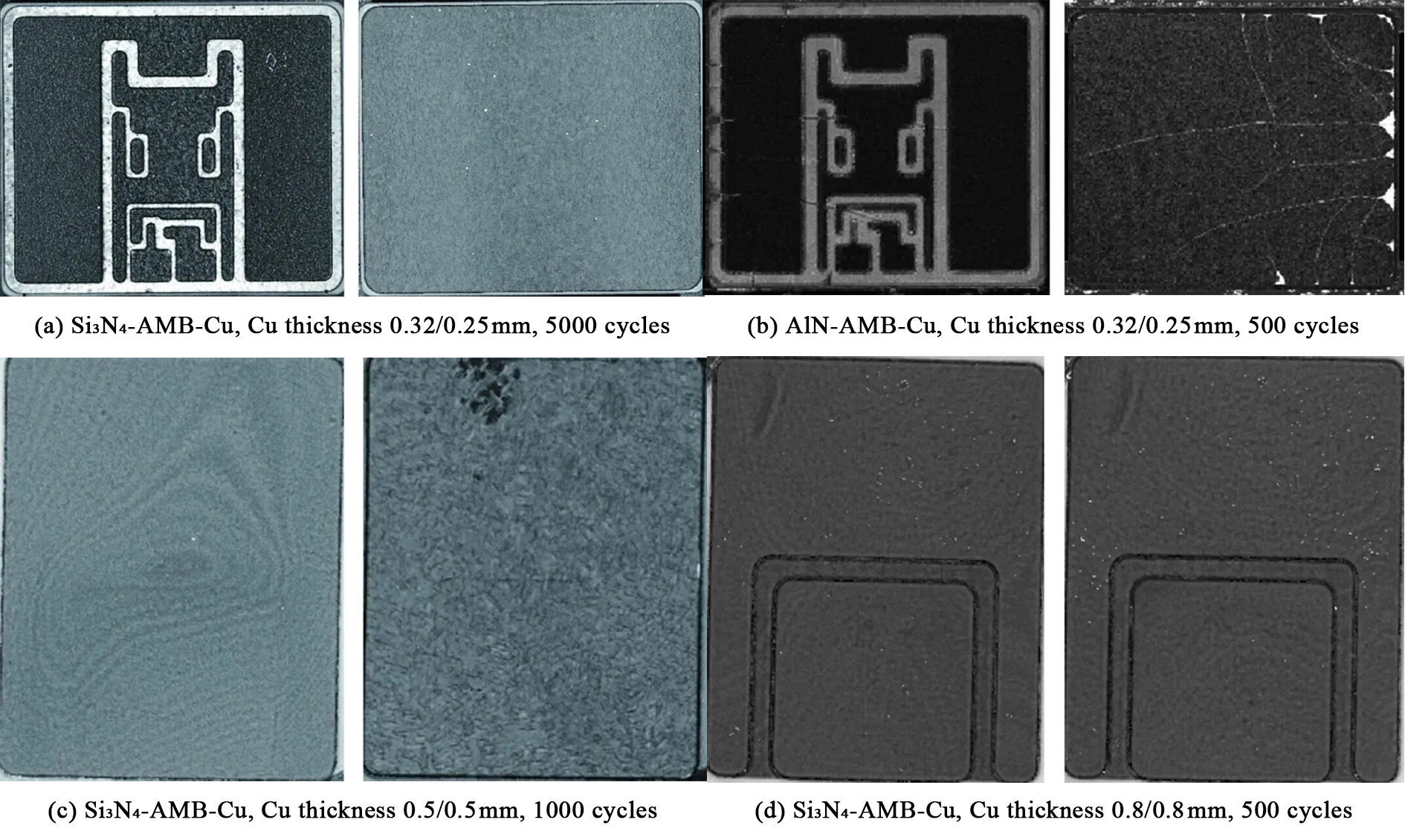

2.2.2 Thermal Cycling Reliability

Under −45 °C to 150 °C cycling:

- Si₃N₄‑AMB‑Cu lifetime: 10× longer than AlN‑AMB‑Cu, 100× longer than Al₂O₃‑DBC‑Cu.

- Even with thick copper (0.8 mm/0.8 mm), samples survived 500 cycles without microcracks.

Table 5. Thermal cycling reliability of Si₃N₄, AlN, and Al₂O₃ copper‑clad substrates

| Copper thickness/mm | Si₃N₄(a) | Si₃N₄(b) | AlN(b) | Al₂O₃(b) |

|---|---|---|---|---|

| 0.3/0.25 | 5 000 | 5 000 | 500 | 50 |

| 0.5/0.5 | 1 000 | - | 100 | 10 |

| 0.8/0.8 | 500 | - | 50 | - |

*Note: Thermal shock temperature is -45-150 ℃; (a) self‑fabricated Si₃N₄‑AMB‑Cu; (b) experimental data of imported products from Japan.

Figure 2. Ultrasonic scan images of Si₃N₄‑AMB‑Cu and AlN‑AMB‑Cu after thermal cycling

(a) Si₃N₄‑AMB‑Cu, Cu thickness 0.32/0.25 mm, 5000 cycles, no microcracks.

(b) AlN‑AMB‑Cu, Cu thickness 0.32/0.25 mm, 500 cycles, microcracks and voids observed.

(c) Si₃N₄‑AMB‑Cu, Cu thickness 0.5/0.5 mm, 1000 cycles, intact without cracks.

(d) Si₃N₄‑AMB‑Cu, Cu thickness 0.8/0.8 mm, 500 cycles, intact without cracks.

3. Conclusion

This study successfully fabricated and systematically evaluated high‑performance Si₃N₄‑AMB‑Cu ceramic copper‑clad substrates.

- Si₃N₄‑AMB‑Cu exhibits comparable thermal conductivity to AlN but superior mechanical strength and fracture toughness.

- Reliability improved by an order of magnitude compared to AlN and Al₂O₃ substrates.

- Exceptional thermal shock resistance demonstrated even under thick copper structures.

Si₃N₄‑AMB‑Cu substrates achieve the balance of high current‑carrying capacity and ultra‑high reliability, making them ideal for next‑generation power electronics, IGBT modules, electric vehicles, high‑speed rail, and smart grid applications.