Sorry, no sales person is available right now to take your call. Pls leave a message and we will reply to you via email as soon as possible.

AMB Ceramic Substrates for High-Power Electronics

Managing heat and reliability is critical in modern power electronics—from electric vehicles (EVs) to renewable energy systems. Active Metal Brazing (AMB) Ceramic Substrates provide a strong, reliable copper-to-ceramic bond and improve thermal performance for demanding applications.

What Makes AMB Different?

AMB builds on Direct Bonded Copper (DBC) technology but achieves stronger bonding. It uses small amounts of reactive metals—such as titanium or zirconium—in the brazing alloy. This creates a direct chemical bond between copper and ceramic, without relying on oxygen or high-temperature diffusion alone.

The result: stronger adhesion, better heat flow, and greater resilience during repeated thermal cycling. In practice, this means longer module life, fewer failures, and more design flexibility for high power density.

Compared to traditional DBC, AMB substrates deliver:

• Higher thermal conductivity

• Much stronger copper-to-ceramic bonding

• Lower thermal resistance at the interface

• Compatibility with thicker copper layers (up to 800 μm)

• Better performance across a wider range of ceramic materials

These benefits translate directly into more compact, efficient, and reliable power modules.

Choosing the Right Ceramic: Al₂O₃, AlN, or Si₃N₄?

Not all AMB substrates perform the same. The ceramic base affects cost, thermal performance, and mechanical robustness.

1. Alumina (Al₂O₃) – Cost-effective for mid-power uses

Alumina balances electrical insulation, mechanical strength, and affordability. Its thermal conductivity is 24–28 W/m·K. It suits applications like LED drivers, consumer power supplies, and industrial controls. Choose alumina when budget matters more than extreme thermal performance.

2. Aluminum Nitride (AlN) – For high-voltage, high-heat environments

AlN excels when heat removal and electrical isolation are critical. Its thermal conductivity can exceed 300 W/m·K—far higher than alumina. Its coefficient of thermal expansion (CTE) aligns well with silicon chips. This makes it ideal for rail traction inverters, HVDC systems, and industrial motor drives. Note: AlN is brittle, so mechanical design must account for this.

3. Silicon Nitride (Si₃N₄) – Premium choice for next-gen EVs

Si₃N₄ offers thermal conductivity over 90 W/m·K and exceptional fracture toughness. Its CTE (2.4 ppm/K) closely matches silicon carbide (SiC), reducing stress during thermal cycling. With AMB and thick copper layers, it enables direct die attachment in compact, high-efficiency inverters for EVs, solar farms, and wind turbines.

In real-world use: AMB-bonded Si₃N₄ dominates EV traction inverters above 600V, while AlN-based AMB substrates remain strong in rail and grid infrastructure.

Why More Engineers Are Switching from DBC to AMB

Traditional DBC relies on an oxide layer to bond copper to ceramic. This layer can weaken under thermal stress. AMB eliminates this weak point by forming a direct metallurgical joint.

| Feature | DBC Substrate | AMB Substrate |

|---|---|---|

| Bonding method | Oxygen-assisted | Active metal reaction |

| Max copper thickness | ~300 μm | Up to 800 μm |

| Thermal interface | Oxide layer present | Clean, low-resistance bond |

| Thermal cycling life | Moderate | Excellent |

| Ceramic options | Mostly Al₂O₃, AlN | Al₂O₃, AlN, Si₃N₄ |

For applications where downtime risks revenue or safety, AMB is essential—not just preferable.

Built for Demanding Applications

At KINJI, we’ve spent years refining our AMB process to meet the toughest industry standards. Our substrates feature:

• Void rates below 1%—critical for consistent thermal performance

• Precision copper patterning down to 100 μm line/space

• Full compliance with automotive standards like AEC-Q200 (via SAE) and IATF 16949

Whether you’re developing an EV inverter, a solar microinverter, or a high-speed train propulsion system, our AMB ceramic substrates give you a reliable thermal foundation you can count on.

Ready to explore how AMB can elevate your next design?

Our AMB substrates undergo thermal cycling tests per IEC 60749-36 (up to 2,000 cycles, ΔT = −40°C to +150°C) with <5% degradation in thermal resistance. The proprietary brazing atmosphere control reduces interfacial voids to <0.8%—verified by X-ray laminography.

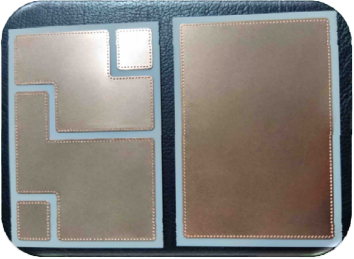

Figure 1: Si₃N₄ AMB – “Best for high-reliability EV power modules.”

Figure 2: AlN AMB – “Top choice for efficient heat dissipation in grid applications.”

Standards & References

• AEC-Q200: Stress Test Qualification for Passive Components (SAE International)

• IATF 16949: Automotive Quality Management

• Thermal Conductivity Data: IEC 60675, ASTM C1113

• Material Properties: CRC Handbook of Chemistry and Physics, 102nd Ed.

→ [Request a sample] | [Talk to our application engineers]

Last updated: November 2025

© KINJI Group – Powering the future, one reliable layer at a time.